PEEK gaskets are essential components in industries that demand high-performance sealing solutions. These gaskets, made from polyether ether ketone (PEEK), excel in extreme conditions. Their ability to resist heat, chemicals, and mechanical stress makes them indispensable in sectors like aerospace, automotive, and medical devices.

In 2025, the adoption of PEEK gaskets is surging. Industries worldwide recognize their durability and eco-friendly nature. For example:

- North America sees a 6.5% annual growth in the PEEK seal ring market.

- Europe’s market value for PEEK gaskets is projected to hit $150 million, driven by sustainability efforts.

- Asia-Pacific anticipates over 7% annual growth due to expanding manufacturing.

These trends highlight how PEEK gaskets address modern industrial challenges while aligning with global sustainability goals.

Key Takeaways

- PEEK gaskets are made from a strong plastic that resists heat and chemicals.

- These gaskets work well in tough conditions, perfect for planes, cars, and medical tools.

- PEEK gaskets last long and need less fixing, saving money over time.

- Their light weight helps save energy, which is good for the planet.

- PEEK gaskets follow strict rules, keeping food and medical use safe.

- Special ways of making them improve how well they work in hard jobs.

- Using PEEK gaskets helps the environment since they can be recycled and make less trash.

- Reliable companies like FLUIDMEC offer top-quality PEEK gaskets for different industries.

What Are PEEK Gaskets?

Definition and Composition of PEEK Gaskets

PEEK gaskets are sealing components made from polyether ether ketone, a high-performance thermoplastic. These gaskets provide reliable sealing solutions in demanding environments. The unique chemical composition of PEEK contributes to its exceptional performance:

- It is a thermoplastic material with high mechanical strength and dimensional stability, even at elevated temperatures.

- PEEK exhibits excellent chemical resistance, making it suitable for harsh environments.

- When combined with PTFE, PEEK gaskets gain enhanced resistance to heat, wear, and corrosion. This combination makes them ideal for high-temperature applications, such as internal combustion engines.

These characteristics ensure that PEEK gaskets maintain their integrity and functionality in extreme conditions, making them a preferred choice across industries.

Key Features of PEEK Material

PEEK stands out among polymers due to its remarkable features. These properties make it a versatile material for various industrial applications:

- High-Temperature Resistance: PEEK operates continuously at temperatures up to 250°C (482°F) and can withstand short-term exposure to 300°C (572°F).

- Chemical Resistance: It resists acids, bases, solvents, oils, and greases, ensuring durability in corrosive environments.

- Mechanical Strength: PEEK offers exceptional strength and rigidity, making it suitable for load-bearing applications.

- Low Friction Coefficient: Its low friction properties reduce wear, extending the lifespan of components.

- Biocompatibility: PEEK is biologically inert, making it safe for medical applications.

- Lightweight with High Strength: It is lighter than metals but provides comparable mechanical strength.

These features make PEEK a reliable material for industries requiring high performance and durability.

Tip: PEEK’s combination of thermal resistance, chemical stability, and mechanical strength makes it a superior choice for applications where traditional materials fail.

Why PEEK Is Ideal for Gasket Applications

PEEK gaskets excel in industrial applications due to their unique properties:

- Superior Thermal Resistance: They operate at temperatures up to 480°F (250°C) without losing mechanical properties.

- Exceptional Chemical Resistance: PEEK gaskets maintain structural integrity in harsh chemical environments, making them suitable for industries like oil and gas.

- Low Moisture Absorption: They resist water absorption, ensuring dimensional stability in humid conditions.

- Abrasion and Wear Resistance: PEEK’s molecular structure reduces friction and wear, extending the service life of gaskets.

- Electrical Insulation: PEEK provides high dielectric strength, making it ideal for electrical components.

- FDA Compliance: Virgin PEEK meets FDA regulations, making it suitable for food processing and medical devices.

These qualities make PEEK gaskets a reliable and efficient solution for sealing needs in various industries. Whether you work in aerospace, automotive, or medical fields, PEEK gaskets offer unmatched performance and longevity.

Key Properties of PEEK Gaskets

Thermal Resistance and High-Temperature Performance

PEEK gaskets are known for their exceptional thermal resistance, making them a reliable choice for high-temperature applications. You can trust these gaskets to maintain their structural integrity even in extreme heat. The material can withstand continuous exposure to temperatures up to 350°F (175°C). For applications requiring even greater heat resistance, reinforced PEEK gaskets exceed this threshold, offering superior performance.

| Material Type | Temperature Threshold |

|---|---|

| PEEK Gaskets | Up to 350°F (175°C) |

| Reinforced PEEK | Exceeds 350°F (175°C) |

This high-temperature capability ensures that PEEK gaskets perform consistently in demanding environments, such as internal combustion engines or industrial machinery. By choosing PEEK, you reduce the risk of gasket failure due to thermal degradation, ensuring long-term reliability.

Chemical Resistance to Harsh Environments

PEEK gaskets excel in environments where exposure to harsh chemicals is unavoidable. Their chemical resistance allows them to endure a wide range of substances without compromising their performance. These gaskets resist:

- Acids, such as acetic acid and hydrochloric acid.

- Bases, including ammonia and ammonium hydroxide.

- Solvents like acetone, benzene, and methanol.

- Hydrogen peroxide (up to 30%).

This resistance makes PEEK gaskets suitable for industries like oil and gas, marine, and food processing. For example, they are commonly used in seals, hydraulic valves, and vacuum pumps. However, you should note that PEEK has limitations when exposed to certain chemicals, such as sulfuric acid in concentrations above 10% or methylene chloride.

By using PEEK gaskets, you can ensure durability and safety in chemically aggressive environments, reducing maintenance costs and downtime.

Mechanical Strength and Dimensional Stability

The mechanical properties of PEEK gaskets set them apart from other materials. These gaskets exhibit remarkable strength and rigidity, even under high-stress conditions. For instance, SRC-PEEK, a reinforced version, offers a modulus of 5.0 ± 0.3 GPa, significantly higher than bulk PEEK’s 2.8 ± 0.1 GPa. This enhanced strength ensures that PEEK gaskets can handle heavy loads without deformation.

Additionally, PEEK gaskets maintain dimensional stability across a wide range of temperatures and pressures. Their high crystallinity (44.2% ± 3%) contributes to their ability to resist wear and fretting corrosion. This makes them ideal for applications requiring precision and durability, such as gears, thrust washers, and supporting rings.

When you choose PEEK gaskets, you benefit from their superior mechanical properties, ensuring consistent performance and a longer service life.

Low Friction and Wear Resistance

PEEK gaskets offer exceptional low friction and wear resistance, making them a reliable choice for applications involving moving parts. The material’s unique molecular structure provides inherent lubricity, which reduces friction between surfaces. This feature minimizes wear and extends the lifespan of both the gasket and the components it interacts with. For example, in automotive systems like brakes and transmissions, PEEK gaskets reduce resistance between moving parts. This ensures smoother operation and enhances the durability of the entire system.

The low coefficient of friction in PEEK gaskets is a key factor in their performance. It prevents excessive heat generation caused by friction, which can lead to material degradation. By reducing wear, these gaskets maintain their sealing properties over time, even in demanding environments. This makes them a superior alternative to traditional sealing materials, which often fail under similar conditions.

In addition to prolonging the lifespan of components, PEEK gaskets also contribute to cost savings. Their wear resistance reduces the need for frequent replacements, lowering maintenance costs. Whether you work in the automotive, aerospace, or industrial sector, you can rely on PEEK gaskets to deliver consistent performance and long-term reliability.

Electrical Insulation and Hydrolysis Resistance

PEEK gaskets excel in applications requiring electrical insulation and hydrolysis resistance. The material’s high dielectric strength ensures effective insulation, even in high-voltage environments. This makes PEEK gaskets ideal for use in electrical and electronic components, where maintaining insulation is critical for safety and performance. For instance, they are commonly used in connectors, insulators, and circuit boards.

Hydrolysis resistance is another standout property of PEEK gaskets. They resist degradation when exposed to water or steam, even at high temperatures. This makes them suitable for applications in humid or wet environments, such as food processing or medical equipment. Unlike other materials that may swell or lose their structural integrity, PEEK gaskets maintain their shape and functionality. This ensures reliable sealing and prevents leaks, even in challenging conditions.

By combining electrical insulation with hydrolysis resistance, PEEK gaskets offer a versatile solution for industries with diverse requirements. Their ability to perform in both dry and wet environments highlights their adaptability and reliability. When you choose PEEK gaskets, you gain a material that meets the demands of modern industrial applications while ensuring safety and efficiency.

Advantages of PEEK Gaskets

Durability and Longevity in Extreme Conditions

PEEK gaskets deliver unmatched durability, even in the harshest environments. Their ability to maintain toughness and dimensional stability at temperatures up to 260°C (500°F) sets them apart from other materials. This makes them ideal for applications involving extreme heat, such as industrial machinery or aerospace systems.

These gaskets also exhibit exceptional tensile strength and impact resistance. They withstand high-pressure conditions without losing their integrity, reducing the risk of system failures. Additionally, PEEK resists corrosive acids and aggressive solvents, ensuring a longer service life in chemically demanding environments. Whether you work in the oil and gas sector or the automotive industry, you can rely on PEEK gaskets to perform consistently over time.

By choosing PEEK, you minimize the need for frequent replacements. This durability not only enhances operational efficiency but also reduces maintenance costs, making it a smart investment for your business.

Cost-Effectiveness Over Time

Although PEEK gaskets may have a higher upfront cost compared to traditional materials, their long-term benefits outweigh the initial expense. Their superior properties, such as wear resistance and chemical stability, significantly reduce the frequency of replacements. This leads to lower maintenance costs and less downtime for your operations.

For example, in industries like food processing or pharmaceuticals, where equipment must operate continuously, the reliability of PEEK gaskets ensures uninterrupted performance. Their ability to resist wear and maintain their sealing properties over extended periods translates to substantial savings.

Additionally, PEEK’s lightweight nature reduces energy consumption in applications where weight is a factor, such as transportation or aerospace. This contributes to overall cost savings while supporting sustainability goals. By investing in PEEK gaskets, you gain a cost-effective solution that delivers value over the long term.

Compliance with Industry Standards

PEEK gaskets meet stringent industry standards, ensuring their suitability for a wide range of applications. Virgin PEEK, for instance, complies with FDA regulations, making it safe for use in food and beverage processing or medical devices. This compliance guarantees that your operations adhere to health and safety requirements.

In the aerospace and automotive sectors, PEEK gaskets meet ISO and ASTM standards for high-performance materials. Their ability to maintain mechanical strength and thermal stability under extreme conditions ensures they meet the rigorous demands of these industries.

Furthermore, PEEK’s environmental benefits align with global sustainability efforts. Its recyclability and long lifespan reduce waste, helping industries achieve their eco-friendly goals. By choosing PEEK gaskets, you ensure compliance with both regulatory and environmental standards, giving you peace of mind while enhancing your operational efficiency.

Sustainability and Environmental Benefits

PEEK gaskets offer significant environmental advantages, making them a sustainable choice for modern industries. By choosing PEEK gaskets, you actively contribute to reducing waste, conserving resources, and lowering carbon emissions. Here’s how these gaskets support sustainability:

- Corrosion Resistance Reduces Waste

PEEK gaskets resist corrosion and wear, even in harsh environments. This durability minimizes the need for frequent replacements. Fewer replacements mean less waste generated over time, helping you reduce your environmental footprint. - Lightweight Design Lowers Emissions

The lightweight nature of PEEK gaskets plays a crucial role in reducing fuel consumption. For example, in automotive or aerospace applications, lighter components lead to improved energy efficiency. This results in lower carbon emissions, aligning with global efforts to combat climate change. - Recyclable and Non-Toxic Material

PEEK is recyclable, which means you can reuse or repurpose it at the end of its lifecycle. Additionally, it has low toxicity, making it safe for the environment during manufacturing, usage, and disposal. This ensures that PEEK gaskets remain eco-friendly throughout their lifespan.

Did You Know?

Using recyclable materials like PEEK helps industries achieve sustainability goals while reducing their reliance on non-renewable resources.

How PEEK Gaskets Compare to Traditional Materials

| Feature | PEEK Gaskets | Traditional Materials |

|---|---|---|

| Durability | High, resists wear and corrosion | Moderate, prone to degradation |

| Environmental Impact | Recyclable, low toxicity | Often non-recyclable |

| Weight | Lightweight | Heavier, increases emissions |

By switching to PEEK gaskets, you gain a material that outperforms traditional options in both functionality and sustainability. Their long lifespan and recyclability make them a smart choice for industries aiming to reduce waste and improve efficiency.

When you select PEEK gaskets, you’re not just choosing a high-performance material. You’re also supporting a greener future. These gaskets help you meet sustainability goals without compromising on quality or reliability. Whether you work in transportation, energy, or manufacturing, PEEK gaskets provide an eco-friendly solution that benefits both your operations and the planet. 🌍

Applications of PEEK Gaskets

Medical and Pharmaceutical Industry

PEEK gaskets play a vital role in the medical and pharmaceutical sectors. Their biocompatibility and resistance to chemicals make them ideal for applications where safety and hygiene are critical. You’ll find these gaskets in medical devices like surgical instruments, diagnostic equipment, and fluid delivery systems. Their ability to withstand repeated sterilization processes ensures they remain effective and safe for prolonged use.

In pharmaceutical manufacturing, PEEK gaskets provide reliable sealing in equipment that handles aggressive chemicals and high temperatures. They resist degradation from cleaning agents and steam, ensuring consistent performance. This durability reduces the risk of contamination, helping you maintain strict quality standards. Whether you’re producing medicines or operating medical devices, PEEK gaskets offer unmatched reliability and safety.

Aerospace and Defense Industry

In aerospace and defense, PEEK gaskets deliver exceptional performance under extreme conditions. Their lightweight nature makes them a preferred choice for reducing the overall weight of aircraft and spacecraft. By using PEEK, you can achieve significant weight savings compared to materials like aluminum, improving fuel efficiency and reducing operational costs.

- PEEK gaskets tolerate extreme temperatures, ensuring safety in high-heat environments.

- Their low thermal conductivity minimizes heat build-up, protecting sensitive equipment.

- They resist corrosion and fatigue, reducing maintenance needs and extending service life.

You’ll find PEEK gaskets in critical components like fuel systems, hydraulic systems, and electrical connectors. Their ability to endure harsh environments ensures reliability in both commercial and military applications. By choosing PEEK, you enhance the safety and efficiency of your aerospace systems.

Tip: PEEK gaskets help you meet the demanding requirements of aerospace and defense industries while lowering long-term costs.

Automotive and Transportation Industry

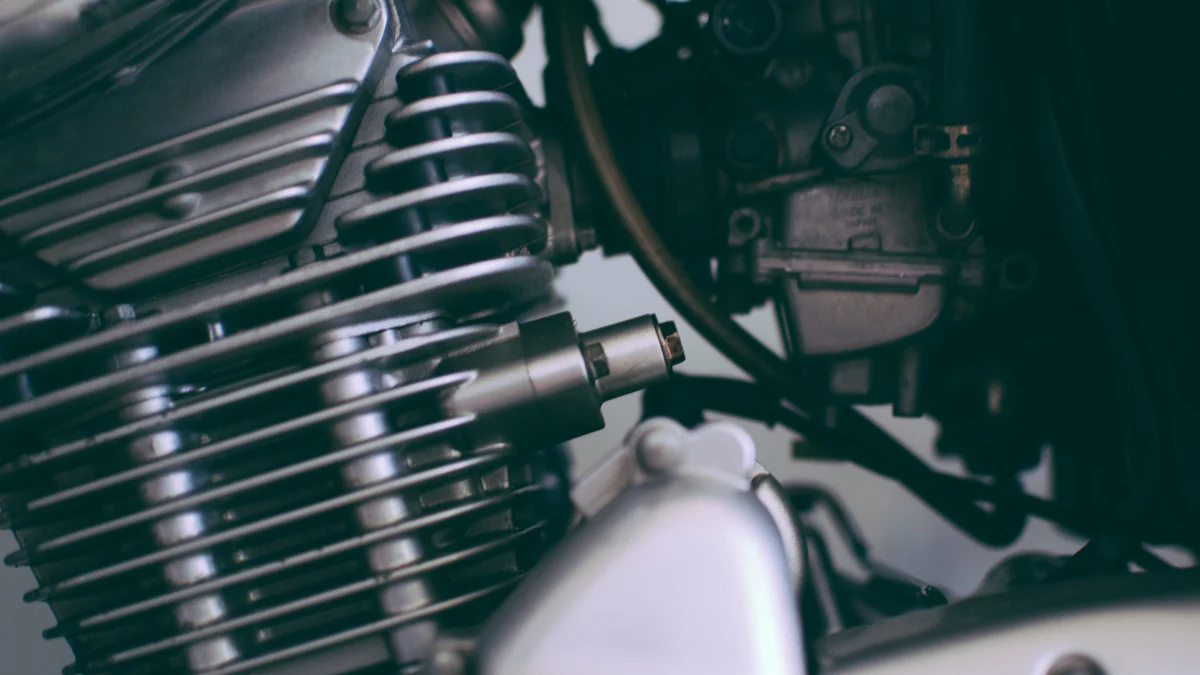

PEEK gaskets are indispensable in the automotive and transportation sectors. Their high-temperature resistance and excellent sealing properties make them ideal for engine components. For example, cylinder head gaskets made from PEEK withstand the intense heat and pressure of internal combustion engines. This ensures effective sealing and prevents leaks, maintaining engine performance.

You’ll also benefit from PEEK’s low friction coefficient, which reduces energy consumption in moving parts. In applications like valve seals and O-rings, PEEK gaskets minimize wear and extend the lifespan of components. A PEEK-PTFE compound has been developed for cylinder head gaskets, offering superior resistance to heat and wear while preventing contact corrosion.

By using PEEK gaskets, you reduce maintenance needs and improve the durability of your vehicles. Their lightweight design also contributes to better fuel efficiency, supporting sustainability goals in the transportation industry. Whether you’re designing cars, trains, or aircraft, PEEK gaskets provide a reliable and cost-effective solution.

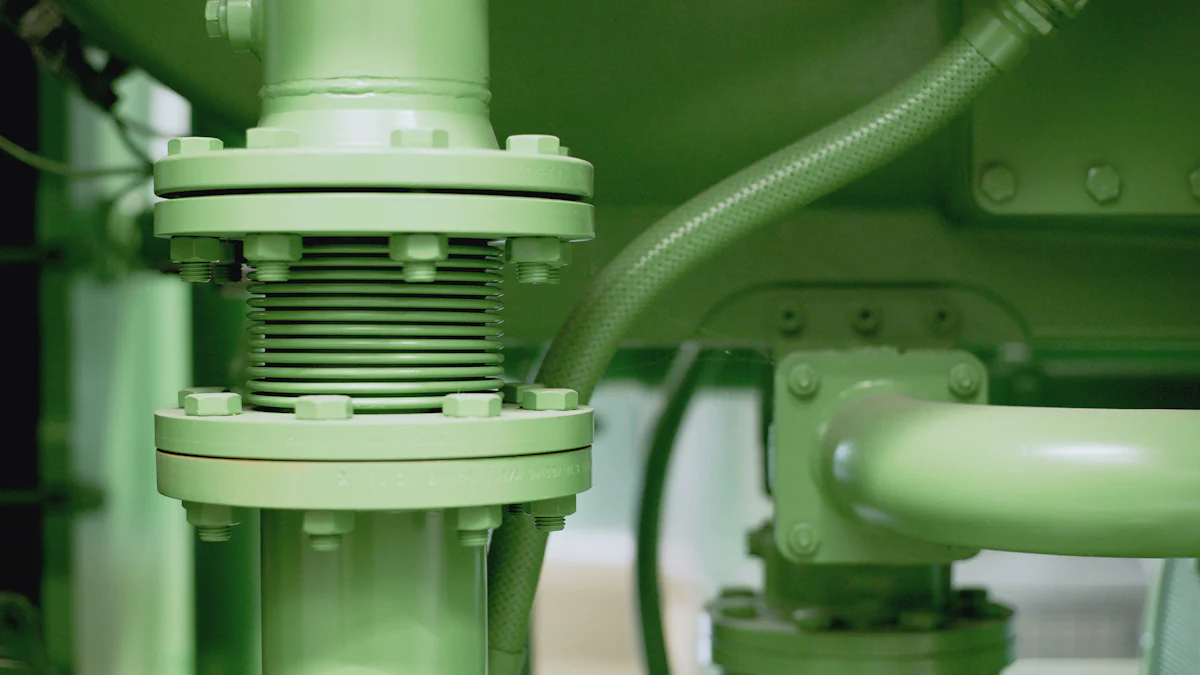

Oil, Gas, and Energy Sector

PEEK gaskets play a critical role in the oil, gas, and energy industries. These sectors demand materials that can withstand extreme conditions while maintaining safety and efficiency. PEEK gaskets meet these requirements with their exceptional properties.

You can rely on PEEK gaskets to provide reliable sealing solutions. They ensure that chemicals and gases remain contained within the system, reducing the risk of leaks. This containment minimizes environmental impact and supports compliance with safety regulations. Their resistance to wear and corrosion enhances the reliability of equipment, even in aggressive chemical environments.

- PEEK gaskets reduce the risk of catastrophic failures by maintaining system integrity.

- Their durability ensures long-term performance, even under high pressure and temperature.

- They resist damage from exposure to aggressive chemicals, extending the lifespan of critical components.

In addition to safety, PEEK gaskets improve operational efficiency. Their ability to maintain a tight seal under extreme conditions reduces maintenance needs. This reliability lowers downtime, helping you achieve consistent productivity. Whether you work in offshore drilling, refineries, or renewable energy systems, PEEK gaskets provide a dependable solution for your sealing needs.

Tip: By choosing PEEK gaskets, you enhance both the safety and efficiency of your operations, ensuring compliance with industry standards.

Food and Beverage Processing

In food and beverage processing, safety and hygiene are top priorities. PEEK gaskets excel in this industry due to their biocompatibility and resistance to food-related chemicals. You can trust these gaskets to maintain their integrity, even when exposed to cleaning agents or high temperatures.

PEEK gaskets contribute to the smooth operation of food processing equipment. Their low friction properties reduce wear on seals and bearings, ensuring efficient performance. This feature minimizes energy consumption and extends the lifespan of machinery.

- PEEK gaskets resist degradation from food-related chemicals, ensuring consistent sealing performance.

- Their biocompatibility makes them safe for use in food and beverage applications.

- They support various components, including conveyor systems, with their durability and chemical resistance.

You’ll also benefit from PEEK’s ability to withstand repeated cleaning and sterilization processes. This ensures that your equipment remains safe and compliant with hygiene standards. Whether used in bottling plants, dairy processing, or packaging systems, PEEK gaskets deliver reliable performance.

Did You Know? PEEK gaskets help reduce maintenance costs by resisting wear and maintaining efficiency over time. This makes them a cost-effective choice for food and beverage manufacturers.

By incorporating PEEK gaskets into your operations, you ensure safety, efficiency, and compliance with industry standards. Their unique properties make them an ideal choice for modern food processing systems.

Material Variations of PEEK Gaskets

Virgin PEEK and Its Characteristics

Virgin PEEK stands out as the purest form of polyether ether ketone, offering unmatched performance in demanding applications. Its unique properties make it a versatile choice across various industries.

Key Characteristics of Virgin PEEK:

| Property | Description |

|---|---|

| Thermal Mechanical Strength | Withstands high temperatures and mechanical loads. |

| Hardness and Rigidity | Provides excellent structural integrity. |

| Creep Resistance | Maintains shape under prolonged stress. |

| Chemical Resistance | Resists most chemicals, ensuring durability. |

| Radiation Resistance | Performs well in high-radiation environments. |

| UV Resistance | Limited; avoid prolonged UV exposure. |

| Vulnerability | Susceptible to halogens and strong acids. |

You’ll find virgin PEEK in applications requiring precision and reliability.

Common Uses:

- Bearings and bushings

- Valve seats and backup rings

- Semiconductor machinery components

- Medical prosthetics and implants

- Automotive and aerospace parts

Virgin PEEK’s ability to handle extreme conditions makes it indispensable in industries like oil and gas, aerospace, and electronics. Its high thermal resistance and mechanical strength ensure consistent performance, even in the harshest environments.

Tip: Use virgin PEEK for applications where purity and high performance are critical, such as medical devices or semiconductor equipment.

Glass-Filled PEEK for Enhanced Strength

Glass-filled PEEK takes the durability of virgin PEEK to the next level. By incorporating glass fibers, this variation offers superior strength and rigidity, making it ideal for applications that demand structural stability.

Key Benefits of Glass-Filled PEEK:

- Increased rigidity ensures components maintain their shape under stress.

- Enhanced strength allows it to handle higher loads compared to unfilled PEEK.

- Improved dimensional stability ensures reliable performance at elevated temperatures.

| Property | Description |

|---|---|

| Rigidity | Increased due to glass fibers |

| Strength | Enhanced strength compared to unfilled PEEK |

| Dimensional Stability | Improved stability, especially at high temperatures |

You’ll often see glass-filled PEEK in industries like aerospace, automotive, and oil and gas. It’s commonly used in precision bearings, piston parts, and pump housings. These applications benefit from its ability to resist wear and maintain structural integrity over time.

Did You Know? Glass-filled PEEK gaskets are perfect for high-pressure environments where maintaining shape and strength is essential.

Carbon-Filled PEEK for Conductivity

Carbon-filled PEEK combines the strength of PEEK with enhanced thermal and electrical conductivity. This variation is lightweight yet strong, making it a preferred choice in industries requiring conductive materials.

Benefits of Carbon-Filled PEEK:

| Benefit | Industry Applications |

|---|---|

| Enhanced thermal stability | Aerospace, Automotive |

| Improved thermal conductivity | Semiconductor, Electrical sectors |

| Lightweight yet strong properties | Aerospace, Automotive |

You’ll find carbon-filled PEEK in engine components, housings, and connectors. Its ability to dissipate heat efficiently makes it ideal for semiconductor and electrical applications. In aerospace and automotive industries, it reduces weight while maintaining strength, improving overall system efficiency.

Tip: Use carbon-filled PEEK for applications where heat dissipation and conductivity are critical, such as electrical connectors or engine parts.

By understanding these material variations, you can select the right type of PEEK gasket for your specific needs. Each variation offers unique advantages, ensuring optimal performance in diverse industrial applications.

Other Modified Grades for Specific Applications

PEEK offers a range of modified grades designed to meet the unique demands of specific industries. These variations enhance the material’s properties, making it suitable for specialized applications. By selecting the right grade, you can achieve optimal performance and reliability in your operations.

Popular Modified Grades of PEEK

Here are some of the most commonly used modified grades and their applications:

- KetaSpire KT 820GF30 PEEK: This grade contains 30% glass fiber reinforcement. It provides excellent dimensional stability and high-temperature resistance. You’ll find it ideal for applications in sour gas environments or high-pressure systems.

- KetaSpire KT 820CF30 PEEK: Reinforced with 30% carbon fiber, this grade offers superior strength and chemical resistance. It works well in medical devices and semiconductor processing equipment.

- Bearing Grade PEEK: Designed for high-wear applications, this grade enhances low friction properties. It’s perfect for bearings, seals, and other moving parts.

- Electrically Conductive PEEK: This grade dissipates static electricity, making it suitable for electronics and semiconductor manufacturing.

- Medical Grade PEEK: Meeting biocompatibility standards, this grade is used in surgical instruments and implants.

Each of these grades addresses specific challenges, ensuring that your equipment performs reliably under demanding conditions.

Key Features of Modified PEEK Grades

Modified PEEK grades enhance the material’s core properties to suit different environments. Here’s how they compare:

| Grade | Key Features | Common Applications |

|---|---|---|

| Glass-Filled PEEK | Enhanced rigidity and dimensional stability | Precision bearings, pump housings |

| Carbon-Filled PEEK | Increased strength and wear resistance | Aerospace components, high-stress parts |

| Bearing Grade PEEK | Superior wear resistance and low friction | Bearings, seals, and moving parts |

| Electrically Conductive PEEK | Static dissipation and thermal conductivity | Semiconductor manufacturing, electronics |

| Medical Grade PEEK | Biocompatibility and sterilization resistance | Medical implants, surgical instruments |

By understanding these features, you can choose the grade that best fits your needs.

Why Choose Modified PEEK Grades?

Modified PEEK grades provide tailored solutions for industries with specific requirements. For example, glass-filled PEEK ensures stability in high-pressure systems, while carbon-filled PEEK offers unmatched strength for aerospace components. Bearing grade PEEK reduces wear in moving parts, extending the lifespan of your equipment. Electrically conductive PEEK prevents static buildup, ensuring safety in electronics. Medical grade PEEK meets strict health standards, making it safe for implants and devices.

Tip: Always evaluate the operating conditions of your application before selecting a PEEK grade. This ensures you get the best performance and durability.

By leveraging these modified grades, you can enhance efficiency, reduce maintenance, and ensure compliance with industry standards. Whether you work in aerospace, medical, or electronics, there’s a PEEK grade tailored to your needs.

Why Choose PEEK Gaskets in 2025?

Technological Advancements in PEEK Manufacturing

By 2025, advancements in PEEK manufacturing have revolutionized gasket performance. These innovations have made PEEK seals more durable, versatile, and resistant to extreme conditions. You can now rely on PEEK gaskets for applications that demand high performance in challenging environments.

- Reinforced composites enhance the strength and wear resistance of PEEK gaskets, making them suitable for high-pressure systems.

- Advanced manufacturing techniques improve the precision and consistency of gasket production, ensuring reliable sealing in critical applications.

- Hybrid materials combine PEEK with other polymers or fillers, creating gaskets with tailored properties for specific industrial needs.

These advancements allow PEEK gaskets to perform exceptionally well in high-temperature environments, such as automotive engines or industrial machinery. They also improve chemical resistance, ensuring long-term reliability in harsh conditions. With these innovations, PEEK gaskets have become indispensable for industries requiring durable and efficient sealing solutions.

Superior Performance Compared to Traditional Materials

PEEK gaskets outperform traditional materials like PTFE or rubber in almost every aspect. Their superior properties make them the preferred choice for demanding applications.

| Property | PEEK | PTFE |

|---|---|---|

| Mechanical Strength | High | Low |

| Wear Resistance | Excellent | Moderate |

| Temperature Stability | Up to 250°C (482°F) | Up to 260°C (500°F) |

PEEK seals exhibit exceptional mechanical strength, allowing them to withstand high pressures and intense mechanical loads. They also resist degradation from aggressive chemicals, ensuring long-term reliability. Unlike traditional materials, PEEK gaskets maintain their properties across a broad temperature range, from cryogenic levels to 250°C (482°F).

You’ll find that PEEK gaskets reduce wear and improve energy efficiency due to their low friction coefficients. This makes them ideal for applications where durability and performance are critical. Whether you work in aerospace, medical, or oil and gas industries, PEEK gaskets provide unmatched reliability and efficiency.

Availability Through Trusted Suppliers Like FLUIDMEC

In 2025, sourcing high-quality PEEK gaskets has become easier thanks to trusted suppliers like FLUIDMEC. You can count on FLUIDMEC to provide PEEK gaskets that meet the highest industry standards. Their expertise ensures that you receive gaskets tailored to your specific needs, whether you require custom shapes or specialized grades.

FLUIDMEC offers a wide range of PEEK gaskets, including virgin, glass-filled, and carbon-filled variations. These options allow you to choose the right gasket for your application, ensuring optimal performance and durability. Additionally, FLUIDMEC’s commitment to quality and customer service makes them a reliable partner for your sealing needs.

By choosing FLUIDMEC, you gain access to the latest advancements in PEEK manufacturing. Their gaskets deliver superior performance, helping you meet the demands of modern industrial applications. Whether you need gaskets for medical devices, automotive systems, or food processing equipment, FLUIDMEC has you covered.

Tip: Partnering with a trusted supplier like FLUIDMEC ensures that you get the best PEEK gaskets for your operations, saving you time and resources.

PEEK gaskets have proven to be indispensable in modern industries. Their unique properties, such as heat resistance, chemical stability, and low friction, make them ideal for extreme environments. These gaskets address critical industrial challenges, ensuring durability, efficiency, and sustainability.

| Property | Benefit in Industrial Applications |

|---|---|

| Heat Resistance | Maintains toughness and dimensional stability up to 260°C (500°F) |

| Pressure Tolerance | Exceptional tensile strength and impact resistance for high-pressure environments |

| Chemical Stability | Withstands corrosive acids and aggressive solvents, ensuring longer service life |

| Low Friction | Minimizes energy loss and wear in dynamic sealing systems |

| Lightweight Nature | Reduces system weight while maintaining performance |

| Customizability | Highly machinable for precision in custom seals |

By choosing FLUIDMEC’s PEEK gasket solutions, you gain access to seals designed for high-pressure and high-temperature environments. These gaskets resist chemical degradation, minimize wear, and outlast conventional materials, reducing downtime and maintenance costs.

Looking ahead, advancements in PEEK manufacturing will further enhance their durability and versatility. Innovations will enable complex designs and better performance in aggressive environments, ensuring PEEK gaskets remain a top choice for industries worldwide.

Tip: Explore FLUIDMEC’s range of PEEK gaskets to meet your industrial needs with confidence and reliability.

FAQ

What makes PEEK gaskets different from other sealing materials?

PEEK gaskets offer superior thermal resistance, chemical stability, and mechanical strength. They outperform traditional materials like rubber or PTFE in extreme environments. Their durability and low friction properties make them ideal for industries requiring reliable sealing solutions.

Can PEEK gaskets handle high-pressure applications?

Yes, PEEK gaskets excel in high-pressure environments. Their exceptional tensile strength and dimensional stability ensure reliable performance under intense mechanical loads. This makes them suitable for applications like hydraulic systems and industrial machinery.

Are PEEK gaskets safe for food and medical applications?

PEEK gaskets meet FDA standards for food and medical use. Their biocompatibility and resistance to cleaning agents make them safe for medical devices and food processing equipment. They maintain hygiene and performance even after repeated sterilization.

How do PEEK gaskets contribute to sustainability?

PEEK gaskets reduce waste through their long lifespan and recyclability. Their lightweight design lowers energy consumption in transportation and manufacturing. By choosing PEEK, you support eco-friendly practices while maintaining operational efficiency.

What industries benefit most from PEEK gaskets?

Industries like aerospace, automotive, oil and gas, medical, and food processing benefit greatly. PEEK gaskets provide reliable sealing in extreme conditions, ensuring safety and efficiency. Their versatility makes them indispensable across diverse applications.

How do you select the right PEEK gasket for your application?

Consider factors like temperature, pressure, and chemical exposure. Choose the appropriate grade, such as virgin, glass-filled, or carbon-filled PEEK, based on your specific needs. Consulting a trusted supplier ensures you get the best solution.

Are PEEK gaskets cost-effective?

While the initial cost may be higher, PEEK gaskets save money over time. Their durability reduces maintenance and replacement costs. Their efficiency in extreme conditions minimizes downtime, making them a smart long-term investment.

Where can you source high-quality PEEK gaskets?

You can source reliable PEEK gaskets from trusted suppliers like FLUIDMEC. They offer a wide range of options tailored to your needs. Their expertise ensures you receive high-performance gaskets for demanding applications.